Quality Control

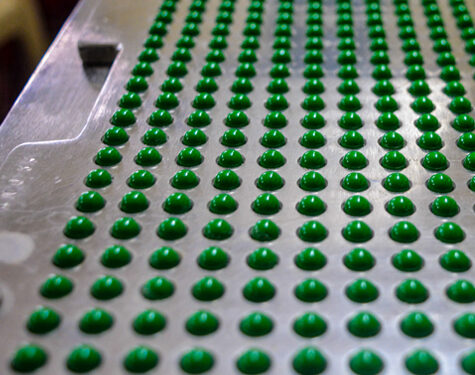

A well-developed Quality Control department has been established at Ayurved Rasayani which ensures that our products are pure, safe and effective and are released only after a thorough analysis. Rigorous efforts are undertaken for quality checking at different stages – raw material standardization, in process validation and finished product standardization.

Quality Control is achieved in compliance with the classical Ayurvedic norms. Use of modern day techniques and criteria add to the reliability of our products. The products are validated using XRD, XRF, SEM, TEM, ICP and GC techniques.

Raw material is first tested in accordance with the classical standardization norms. Only the raw material which passes these norms is selected. Unlike other companies, we do not buy Active Pharmaceutical Ingredients (API) from the market, but we produce our own API. This is indeed the backbone of our desire to manufacture best quality and safe medicines. In process validation is carried out meticulously. Final product standardization as well as testing of packaging material is done. The medicines that pass through this journey of rigorous checking are then packed for sale. With such stringent regulations in place, the safety and efficacy of our products is well assured.

INWARD RAW MATERIAL TESTING

- External morphology is used to identify the plants by physical viewing.

- Microscopy – examination under microscope is done to ascertain the identity of the plant and rule out adulteration.

- Ash Value – residue of the substance – toxicity of the component is determined by its Ash value.

Therefore, it is very important to evaluate the Ash value to estimate its safety. - Extractive Value – Percentage of Kadha extract – from the initial water added to the mixture of plant components.

Total dissolved solids present in the Kadha can be evaluated to maintain the standards of the medicines. - Phyto Constituents – Chromatography analysis is used to detect the active ingredients in percentage – quality and quantity of the plant constituents.

MATERIAL TESTING

This is done for the plant material and also for the finished goods. Material analysis is done by advanced analytical technique for quality and purity of raw material and finished products as per the specifications of API and AFI.

- Average Weight Variation - Uniformity of weight is an important in-process test parameter that ensures consistency of dose and its therapeutic effects. Weight variation of tablets with respect to dose is extremely important and its variation is reduced to a minimum. Herbal tablets have a high possibility of disintegration. As per the API/ AFI norms the permissible limit for such variations has been stated. We try to constantly improvise so as to have minimal loss in weight variation.

- Disintegration Test - Disintegration testing determines whether tablets or capsules disintegrate within a defined period of time when placed in a liquid medium as per the specifications of Indian Pharmacopoeia. If it takes longer it would take similarly long time for disintegration in the body which is not advisable.

- Friability Test - This is to check the brittleness of the tablets, particles detach – tester to rotate tablets to evaluate the friability is permissible.

- Hardness of Tablets - Tablets are subjected to specific force to break them into big pieces along the breaking indent line. Tablets are pressed hard by specific force to test the hardness of the tablet. The extent of breakage decides its permissibility.

- Weight variation -

The average weight variation is specified and the testing is done as in case of tablets. - Standard dose -

This is also done as specified by the AFI. - Blister Testing - Check leakages in the blister packing to avoid damage to the medicines especially by water and air leakages.

- Active Material (Organoleptic test) - The appearance, colour, odour, water solubility and pH neutrality test are conducted of the finished medicines. This must adhere to the AFI /API norms.

- These medicines are tested as per plant material stated earlier.

Appearance Testing - Physical testing is done to check the colour, clarity, odour of oils.

Specific Gravity Testing - Specific Gravity” (SG) is used to weigh the density of a liquid in comparison to the density of an equal volume of water at a specified temperature. Specific gravity of medicated oil shows the total amount of material dissolved in oil as compared base oil used for formulation. The temperature used for measurement is usually at 39.2oF (4oC), since this temperature allows water to assume its maximum density. This testing is to check the amount of phytoconstituents. The procedure begins by weighing the oil before the manufacturing the medicinal oil. It is again weighed to check its increase. The difference in the weight is the presence of phytoconstituents. The phytoconstituents are the medicinal elements added to the oil and they should be present in specific values to get the desired results.

Refractive Index - Polarity of the oil is measured by specific machinery.

pH Value of Oils - It is tested by sensors to detect its pH value directly. It should always be neutral.

Iodine Value & Acid Value and Saponification Value - Linoleic and linolenic acids (fat) of oils is measured using titration method. Iodine, fat content and acid content in the oil is also evaluated.

Two Types of Tests :

- Granthokta Test

- Chemical Test

- Granthokta Testing -

a. Varna - by observation of the physical appearance and to tally with the features described in the granthas.

b. Rekhapurnatva - testing of the bhasma is done by holding it in a pinch to see if it fills up the fingerprints at the tips. If it has become a fine powder, it does fill the finger prints to complete the test.

c. Nishchandratva - The bhasmas are observed under specific light. If it is devoid of any lustre and shine then the bhasma process is considered to be complete.

d. Niswadu - The word means tasteless. The medicine is tested for its taste it should be tasteless to be considered as good quality bhasma, especially in case of Sudha varga.

e. Varitaratva - The Bhasma particles should be so fine that they should float over the water surface.

f. Nirdhum (Charcoal Cavity Test) – Bhasma or the Rasa Kalpa is added to sodium carbonate and burnt, Smoke should not emit from the burnt substance, only then it is considered to be complete.

g. The diameter of Paral, the thickness of the Paral depends on the 2 factors :

1. The Bhasma Dravya that need to undergo maran.

2. The weight / amount of Dravya that is used for the purpose. - Chemical Testing

a. Appearance - Physical appearance should match the prescribed colour.

b. Total Ash - The residual weight of ash after complete combustion of the drug is measured to evaluate the net weight of the product. If it is within prescribed parameters then the medicine is considered to be tested okay for packing.

c. Acid insoluble ash - The percentage of ash that is soluble in acid is measured. It shows the solubility and disintegration of the medicine when it reaches the stomach and subjected to gastric acids. The undissolved drug should be within prescribed parameters. Ayurveda Rasayani strives it to be 100 % soluble in acid.

d. Loss on drying (LOD) - The moisture content should be less than 5 % of the drug in order to avoid fungal and bacterial growth on the medicine. Hence the humidity and water content is reduced from the medicine by thoroughly drying the medicines.

e. Assay - The purity of material is measured by the assay method. 98% of the purity of the material is maintained for raw materials as well as the finished medicines.

f. pH - The pH of the medicine is always maintained at neutral; care is taken not to allow it to be acidic or alkaline.